Three Important People

in the History of Willys Overland

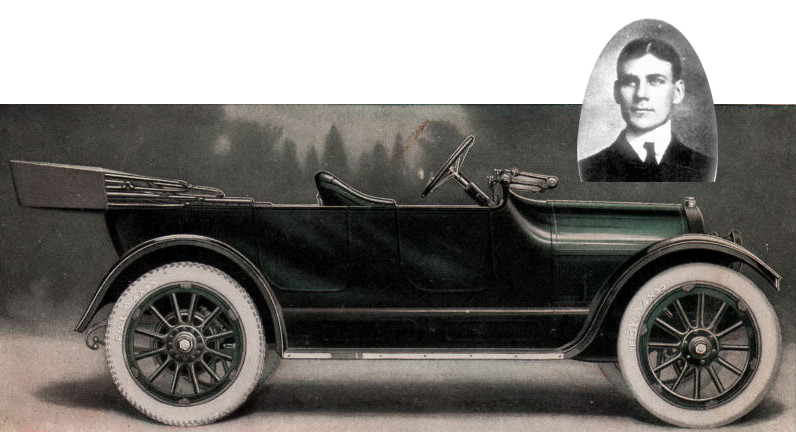

Claude E Cox

1879-1964

A dearth of reliable records diminishes our ability to declare definitively whether or not Claude Ernest Cox ever produced an automobile under his own name. Maybe he did. There’s some indication that, at least for a while, as he was engrossed in the intensive basic research for which he deserves to be remembered, Cox may indeed have built a cyclecar or full-size car–or perhaps both–in at least prototype form in 1914, while trying to rope in some investment cash.

Cox possessed one of the most fertile and analytical minds in the early history of automobile design. He had a strong hand in the creation of some significant early cars.

Born in Libertyville, Indiana in 1879, Cox enrolled in Rose Polytechnic Institute in Terre Haute, at the western part of the state. A relatively small but acclaimed college, known today as Rose-Hulman Institute of Technology, it was the first fully accredited engineering school established west of the Allegheny Mountains. Cox authored his mandatory baccalaureate thesis on thermodynamics in road engines, supporting it before his distinguished graduation in 1902 by hand-building a car out of thrown-out bicycle and motorcycle components. His professional career started with the Standard Wheel Company of Terre Haute at 671 Ohio Street whose president, anticipating a move into the ranks of automotive suppliers, created a new department on powered-vehicle components under Cox’s direction. Its first project was the creation of a new automobile, christened by Cox as the Overland, which rolled through Terre Haute in early 1903. The first Overland had a 5 H.P. front-mounted engine and an epicyclic transmission, (which strongly suggested the gearbox that the Model T later made all but universal). The engine sprouted a second cylinder by 1904 in a revised model that gave speeds of up to 20 mph. It lacked fenders initially.

Sales were tepid; in 1904 a boiler explosion occurred; Standard Wheel’s moneymen lost interest and eventually terminated the venture with Cox, who took on potentially ruinous debt to buy Overland outright for about 8 or 9,000 dollars in 1906.

More financial backing was required, and this came from David M. Parry, who had achieved reputed millionaire status through manufacturing 2-wheel horse-drawn carts, and was then the nation’s largest carriage producer. He had also dabbled in cars. In early 1907, Parry agreed to underwrite Cox’s tottering firm, paying off Standard’s liens on the Cox debt. The company was incorporated with David having 51% of the share and Claude 49%.

It was at this time that John North Willys arrived on the scene as he had ordered 500 Overlands and put down a deposit of $10,000 and was wondering where his cars were. A very early automotive retailer, Willys was selling cars in Elmira, New York. Introduced to Parry, Willys agreed to buy the newly reorganized Overland Automobile Company’s entire production run for 1907–it came to 47 cars–and resell it. All looked charming until a financial panic upended American financial markets later that year, corking the trickle of Parry’s money. Parry’s empire that had been keeping Cox in business folded. Overland simply didn’t have the money to build cars that buyers, through Willys, had already ordered.

Willys knew that, financially, his own neck was on the stump along with Cox’s. He traveled to the Overland factory in Indianapolis to confer with Cox. The story goes that Willys convinced the operator of the hotel where he was staying to cash a personal check, covering Overland’s payroll and thereby rescuing the firm. Willys quickly rounded up a new consortium of investors, led by carburetor producer Frank Wheeler, who bought Overland and installed Willys as president in exchange for most of the stock held by Cox and Parry.

Cox thus disassociated himself with the re-formed Willys-Overland. It was 1909, and Cox moved on to the Inter-State Automobile Company in Muncie, Indiana, founded in part by the creators of the Mason jar. By the end of the year, he was gone from that position, too. Cox had done some of the groundwork on a six-cylinder Inter-State car that debuted in 1913, but by then, he’d moved on to design a massive truck–or Trux, as the builder called it–for H.E. Wilcox of Minneapolis.

Anxious to do the sort of pure research on which he’d founded his education and career, Cox left Wilcox in 1913 and set up Commercial Engineering Laboratories in Detroit, specifically in the Boyer Building, which coincidentally also housed the early administrative offices of General Motors.

History indicates that Cox did a lot of analytical work for GM as a subcontractor. One of GM’s first research laboratories in Detroit was operated on a consultancy basis by the famed chemical engineer Arthur D. Little, who, with Cox’s support, organized the first research facility for GM.

As GM’s labs grew, Cox shifted to manufacturing test instruments, measuring fluid and gas flows with unchallenged accuracy. The company grew exponentially, and merged with another test-instrument firm, the George L. Nankervis Company, in 1955. Cox retired the following year, but remained a consultant with the firm until he died in 1964 in Beirut, Lebanon, after he was stricken while on a cruise of the Mediterranean with his family. The business he founded in 1913 is still highly active today, having been reorganized in 1969 as Testek Inc., and based now in Livonia, Michigan.

Some of Cox’s contributions to designing and building vehicles may not have outlived him, but are still highly noteworthy as accomplishments. Most of us know that Willys-Overland, though in greatly recast form, lives on as Chrysler’s storied Jeep brand. Cox was gone, but Inter-State built cars under its own name until World War I halted production. Afterwards, GM bought Inter-State’s Muncie plant and used it to build the Sheridan, before selling the factory to William C. Durant, who built the Durant Six on the property. As for Wilcox, it became an early overhauling contractor and holding company for Greyhound, for which it had designed an early intercity passenger bus.

Taken from: hemmings.com.blog.artice.claude.e.cox and wikipedia

John North Willys

1873-1935

John North Willys (pronounced Willis) was an enterprising individual from the beginning. He bought and sold items profitably even as a child. He saved nearly every penny he earned, unless, items were needed in the household, or his personal needs had to be attended to, which would include his own shoes and clothes.

1873 was an economically tough year in the United States. The collapse of the strung-out Jay Cooke railroad empire started a cascade of failures in banks, railroads, and other business that resulted in an economic depression that lasted through 1879. Of the 490 major banks in the country, 89 failed outright. Panic ensued, causing investors to dump stock. With no money to back it, the New York Stock Market collapsed, closing for ten straight days until the run subsided.

Earning money was not easy. Unemployment soared to 14%; jobs were hard to find

This is the era in which John Willys grew up in. At age 15, in 1888, he approached his parents about becoming a partner with a friend in a laundry in a nearby town. He was so convincing that his parents agreed. He moved into an apartment which came along with the laundry operation in Seneca Falls, NY. He and his partner successfully operated the laundry for a year, doing business even on Sundays. At the end of a year, they sold the entire operation and made a profit of a thousand dollars, which was split between the two partners. His parents expected him to further his education with that money. Several colleges were close by, one of the best being at Elmira. John set out to become a lawyer. He was able to pursue a couple of years of college education before his father died. At 18, John had to return home to support his mother and other siblings.

Not one to work for someone else, Willys saw an opportunity in bicycles. A craze for them was sweeping the country. He rented a small space in Canandaigua for his sales room; he adapted quickly to methods that earned him profits while keeping more of his own money. Within a very short time, he expanded into repairs of bicycles, which included selling parts and dress up kits. Within a few months, he moved his operation to Main Street. As an agent for several different bicycle manufacturers, he was well informed when some of them invited him along in their ventures into automobiles. In 1896, he became an agent for a company out of Boston that sold rubber hoses; they were braided, which greatly increased their tensile strength and longevity. It would later become the basis for automobile “balloon” tires. It is not known if Willys pursued that aspect of the company or not. Presumably, given his penchant to find winners, he had some interest in rubber balloon tires.

In 1897, he married a local girl named Isabel Van Wie. They had one child, a daughter named Virginia.

In 1898, Willys purchased a bankrupt sporting goods operation in Elmira, in a great location. He expanded his bicycle business there, and it boomed, often selling the entire year’s production of cycles from a couple of different factories.

In 1899, while visiting a business in Cleveland Ohio, he saw his first automobile going down a city street. He was fascinated. Willys noted the total immense interest of every person that saw the car going by. He didn’t get bitten by the “bug” that often accompanies seeing a new car, but upon consideration of what he observed, Willys made a conscious deliberate decision that automobiles would be the next “big” thing in the country, quickly replacing bicycles, horses, and railroads.

By 1900, at age 27, he had greatly expanded, with a sales staff selling bicycles all over the eastern United States, to the tune of over $500,000 a year. He purchased a Pierce automobile (made by fellow bicycle maker George Pierce) from the factory in Buffalo for $900 and used it in demos as an agent to sell the Pierce cars. He sold nothing in 1900. In 1901 he sold two cars.

Anyone else may have given up, but he took on a Rambler franchise in 1902; between the two makes, he sold 8 cars (and twenty in 1903). People at that time were slowly overcoming their initial resistance, skepticism, and lack of trust in long term financing to satisfy their deep desires to own, or be the first to own, an automobile. The Rambler was made by Thomas Jeffery, another bicycle man, located in Chicago; Willys had sold many Rambler bicycles. Jeffery had started a car factory in 1900 in Kenosha; the Rambler car of 1902 had the engine under the seat, but was well built, and reasonably priced.

Jeffery was an innovator, the first to move the engine to the front of the car, and to make the steering tiller into a steering wheel, easing driving into a near unconscious effort. By 1904, Willys could not get enough of Jeffery’s cars; and his other supplier, Pierce, had decided to move his cars upscale, coming out with a Pierce-Arrow model for 1904. Willys decided that to counter this, he would contract the entire output of a reasonably priced company to ensure a constant supply for his quickly expanding sales network.

Encountering a business acquaintance, Willys learned of a company owned by Standard Wheel that had acquired a car built by Claude Cox which had been named the Overland. Familiar with Standard Wheel, which had an excellent reputation, Willys laid plans to make the Overland his sole source of cars, contracting the entire output of the factory. It was unfortunate that he didn’t reference his source, to see what problems might lie ahead.

A boiler explosion in the Overland factory disheartened the Standard Wheel directors in 1904. They lost interest, and the Overland went for a course set in ultimate bankruptcy. Before the papers were filed, the originator of the car, Claude Cox, purchased the company for $8,000. He modified the production area, and manufactured the cars via additional financing from David M. Parry. Parry had achieved reputed millionair status through manufacturing 2 wheel horse-drawn carts and was then the nation’s largest carriage producer. He agreed to underwrite Cox’s tottering firm paying off Standard’s liens on the Cox debt. The company was reorganized in 1906 and early 1907 as the Overland Company with Parry owning 51% and Cox 49%. Willys sold Overland cars as fast as they could be shipped. A short but hard recession badly hurt David Parry, to the extent that he could not capitalize the Overland Company any further. Production ground to a halt, employees waited for their pay, while Cox desperately sought investors to keep Overland afloat.

Willys had banked upon Overland. In 1906, he sent a $10,000 check to the company to ensure that he got the cars he needed to sell. All of a sudden, in November, shortly before Thanksgiving, shipments stopped, and no one was responding. John Willys got on the train, heading for the plant in Indianapolis.

Willys arrived on a Saturday. He was horrified at what he found, 45 cars sat on an assembly line, not finished. Parts were strewn about. Workers had not been paid. Checks had been sent out to the factory workers, but the bank account was some $350 short to meet all the pay. Claude Cox was despondent. Willys toured the entire facility. All the components were present to continue production of the quality Overland if, and it was a big if, financing could be found.

Taking a risk, after assessment of the situation, Willys, the story goes, convinced the operator of the hotel where he was staying to cash a personal check, covering Overland’s payroll and thereby getting the company back running. He called his financial friends back in Elmira. Based on his word, quick plans were laid out, and the funds were made immediately available the very next Monday for Willys to get the company back on firm ground. The investors were led by carburetor producer Frank Wheeler who bought Overland and installed Willys as president in exhange for most of the stock held by Cox and Parry. Meanwhile The ability to raise $3,500 in one day convinced Overland’s creditors, who were owed about $80,000. Willys was able to convince them to hold off so that he might get the company going. Working quickly, the production line was started, the workmen paid, along with a Thanksgiving bonus, and shipping of new Overland cars resumed. Cox disassociated himself with the re-formed Willys-Overland Company in 1909.

With Willys already accounting for the entire output of the 46 1907 cars, sales were positive. Staying on the scene, alternating between Elmira and Indianapolis, Willys saw production increased ten times to 465 new Overland cars. They were immediately shipped, having all been sold by Willys at $1,200 apiece. Realizing what he had, Willys made arrangements to buy the Overland company, renaming it Willys-Overland Company. His production had to increase with an ever-enlarging demand for Overland cars through other outlets. He built a new factory in 1908, only to realize it had already been outgrown as it came on line!

Willis recognized that he had to quickly move to meet demand or lose the orders. He thought he had made an exceptional deal when he acquired the Marion Car Company in Ohio in early 1909. On board was an excellent engineer and automotive whiz by the name of Harry M. Stutz. Stutz had his own plans in mind, and left to form his own company.

While formulating plans at re-organization of the Marion Company, a prize acquisition landed right on Willys’ lap. The Pope Motors factory in Toledo, Ohio was modern, large, and set up for automotive production. It was also bankrupt so Willys was able to acquire it for $285,000. It became the centerpiece of the “new” Willys-Overland Company.

Willys was able to recoup most of his initial $285,000 purchase outlay by selling off surplus. Willys got the Overland model 38 into production at Toledo on October 26, 1909, one day after his 36th birthday. This particular model had a sliding gear transmission, replacing the epicylic type.

The same year, 1909, Henry Ford introduced his Model T which had an epicylic transmission. For the model years 1910 through the end of the Ford Model T production in 1927, the Overland car was second in production only to the Ford. Henry kept dropping his prices, mostly by finding a means to produce the T cheaper by cutting items, using less expensive parts, or overlapping some process. There was rumor of Ford engaging in questionable labor practices including advertising but not paying high rates. Overland did not do this.

With regard to quality, the Ford was considered somewhat unreliable, but easily repaired by your average farm boy, even at the butt end of all the jokes aimed at the “Tin Lizzie.” However, the Overland was a superior car, and enjoyed a better reputation, even if it was more expensive.

By the end of 1910, Willys-Overland was producing over 4,000 cars a year, all of which were already sold when produced, and ended up with a profit of over $1 million. John North Willys had literally snatched Overland from the jaws of sure death, to a solvency of capitalization of one million dollars! All done within about a year. There was no debt, Willys having paid it all back. Business leaders and banks were ecstatic.

Willys himself was a hard-driven man who did not slow down. His doctors had to order him to take vacations. His personal work ethic was for 7 days a week, mostly 12 to 16 hours a day.

1910 production was 15,500 cars. By 1915, production was 150,000. Willys employed 18,000 people in Toledo, and 20,000 more in his plants in Elyria Ohio, Buffalo NY, and Flint and Pontiac MI. He re-organized the company in 1917, making it a holding corporation, so that he could acquire suppliers such as Auto-Lite spark plug company, putting a lot of them under his control. He also expanded, so that now his factories were producing 1,000 cars a shift. He often stated that he could catch and surpass Ford with a more powerful car that was better appointed but never really exerted the effort. As it is, Willys apparently came in as the #2 automaker from 1912 to 1917.

In 1915 he built a seven-story headquarters in Toledo, OH that was the most modern of its day. Before the end of the decade, one-third of the city of Toledo’s workforce was employed either at Willys-Overland or at one of the numerous small businesses providing parts and supplies.

In 1913, Willys took a doctor ordered vacation to Great Britain. On the ship crossing over, he met Charles Knight, who had been manufacturing engines based upon a “sleeve valve” that replaced the traditional poppet valve used by all other manufacturers, including Willys-Overland. By the end of the voyage, Willys was nearly convinced of the advantages of the sleeve valve engine. He hired a chauffeur driven Knight car, putting 4,500 miles on it over the 15 days he was in England, a feat in itself, given the state of roadways at the time. At the end of the trip, Willys was thoroughly won over. However, he did not intend to pay a lot of royalties for use of the sleeve valve engine.

Casting about, he found that the ownership rights to the Edwards Motor Car Company located on Long Island, New York were for sale; they already had the license to make sleeve valve engines. Willys bought them out, and began to set up operations to produce them at his Elyria Ohio facility, eventually closing the Long Island plant.

The sleeve valve eliminated the poppet, which meant no valves, no valve springs, lifters, push rods, or valve rocker arms. It meant a center location for the spark plug on the head. This increased volumetric efficiency, making more power with less compression. It also meant avoided sludge and carbon deposits.

In 1914, Willys was producing a six-cylinder sleeve valve engine sold under the Willys-Knight name, based on the Edwards-Knight engine. The price range was around $2,500 for a nicely appointed sedan. In 1915, Willys moved the production of the car itself to Toledo, but the Elyria facility, once owned by Garford Manufacturing (and acquired by Willys), kept on manufacturing sleeve valve engines. A 4 cylinder was introduced. In 1917, a V-8 of some note for its power (model 8-88) was introduced, and was sold through 1919, with total production of 2,750 units; a six cylinder (model K-18) was developed but never produced, while an Overland Six was.

Through his holding company, in 1918 John Willys acquired the Moline Plow Company of Moline, Illinois, which manufactured the “Universal” brand of farm tractor and a line of Stephens cars. World War I saw Willys engaged in the manufacture of tugs (tractors) at the Moline facility under contract for the military. They retooled from the military contracts to manufacture well made, reliable, tough tractors and farm implements. (Willys sold the company in 1921-22 and would eventually merge with two Minneapolis companies to form Minneapolis-Moline, which was taken over by White Motors in 1963; the name was finally dropped in 1974.)

The following year he acquired control of the Duesenberg company primarily to get his hands on Duesenberg brothers’ factory in Elizabeth, New Jersey where he planned to produce a new six-cylinder car. The factory which had been built in 1917 to build aircraft engines for the war, and was no longer needed. The Deusenbergs sold their engine company to Rochester Motors of New York, and moved to Indianapolis. Willys Corporation bought the plant and spent $8 million on retooling and developing a new six-cylinder car.

Willys always got along with the labor on the floor, but he was also always around, with his 14 to 16-hour work ethic for seven days a week. With his move to New York City in 1919, the quality of interaction declined, and huge labor unrest arose at the Toledo facility. It dissolved into a prolonged, ugly strike at the plant in 1919, shutting down the plant for several months, causing a riot, which was finally quelled by local police, along with intervention of Federal Courts, as the Governor threatened National Guard activation.

With a combination of these factors, a short, but deep recession caught Willys short for the first time. He had overextended. His nervous creditors moved into immediate receivership. Willys set about to rectify the situation. In the interim, Willys was forced to deal with the creditors’ appointed agent, who had the authority to run the company, Walter P. Chrysler. Chrysler had essentially retired from Buick in 1920, after repeated clashes with W.C. Durant. He certainly did not need a job or more money, having amassed a fortune from Buick stock and several railroad investments.

Aware of his abilities, the bankers approached Chrysler to bring Willys-Overland out of receivership, and save it from total bankruptcy. Chrysler considered the proposal. Perhaps out of a desire not to be hired, he demanded an outrageous salary of $1 million per year for the two-year contract, to be paid no matter what the outcome of his efforts was. The bankers didn’t blink.

John Willys wasn’t happy to have to deal through Chrysler to get anything done. He also held a certain amount of distrust about Chrysler’s true motives. Chrysler felt that to bring Willys-Overland out of their situation, besides selling off assets, a totally new car was needed. Willys-Overland engineers were busy reworking the present Willys 6 (model 89), but the general agreement was that the car left much to be desired. The frame had been patched up but was still weak, and the engine was not noted for either reliability or power. The decision facing Chrysler was pour more money into the Willys Six, or start with a clean piece of paper. Chrysler convinced the bankers the latter was the best move.

As it happened, three young engineers soon landed at the Elizabeth plant with a clean-sheet car design, well into the planning stage. It had a totally new six-cylinder engine with high compression. Further, the chassis was to have four-wheel hydraulic brakes.

John Willys recognized the work of the three “musketeers” as they called themselves: Zeder, Skelton and Breer (ZSB). It was a point that Willys and Chrysler agreed upon. The plan was presented to the bankers. Nervously, within a few weeks, they rejected it. They felt that something more “tried and true” should be built instead of a totally new untried car. Willys shrugged and set back to regaining control of his company and the company fortunes.

Chrysler had a little more on his mind. He intended the new car to be sold as a Chrysler, and had already placed ads in trade newspapers in 1920 and 1921 for the Chrysler Six, “a product of the Willys Corporation.”

John North Willys had a formidable reputation as an honest, hard working, caring man. When Chrysler attempted a stock takeover to force Willys out, the stock holders rejected the concept out of hand, turning Chrysler decisively away. He had by then been approached by the Maxwell-Chalmers Motor Company, which was also deeply overextended, and in danger of going under.

Bankers are bankers. Seeking to protect one another, lest any money be lost between them, they agreed to allow Chrysler to work outside the Willys-Overland contract on the Maxwell-Chalmers situation. Chrysler saw another opportunity with the Maxwell, with special focus on the lackluster Chalmers. Bankers were holding a large block of stock in Chalmers and Maxwell, besides extending credit money to them both. Chrysler knew this, and that they only had credit money involved in the Willys-Overland deal.

Chrysler set about to get Willys-Overland back on track. By 1921, he had reduced the Willys-Overland debt from $48 million down to $18 million. He then left.

Free now from Willys-Overland, he concentrated on Maxwell. Quietly, he began by buying stock from the bankers; most of it, not enough to gain full control, but close. He maintained constant contact with the ZSB engineering team. They continued development of the new high compression engine car in Elizabeth.

Willys-Overland needed cash three months after Chrysler left them for Maxwell. Some said Chrysler had set it up to fail, since he knew that the plant in Elizabeth would be among the items that would be sold. The Elizabeth plant did go up for sale, along with Willys-Overland New Process Gear Company in Syracuse.

Chrysler sent a representative to the bankruptcy auction at Elizabeth. The agent was to offer no more than $5 million for the $14 million facility. Unexpectedly, some very strong competition was encountered. The sale was completed when W.C. Durant (of General Motors and Chevrolet fame) won with a bid of $5.2 million, ultimately producing the Flint car there. The three engineers remained, but the Flint was in no measure anything compared to the proposed Chrysler car.

With the $5.2 million from the Elizabeth sale, and $10 million from the New Process Gear Company sale, John Willys was able to bring Willys-Overland back to profitability in early 1922. He set about to build a second automobile empire from there, and Willys-Overland car continued on its successful path. Although very profitable, John Willys’ businesses were highly leveraged, expanded, and/or acquired through massive borrowings. Yet, by 1923, Willys Overland Company had over $12 million profit.

In 1925, John Willys bought the F.J. Stearns Motor Company of Cleveland, OH, which made luxury autos. They had been utilizing the Knight Sleeve Valve engine since 1911. They were every bit as refined as Packard or Pierce-Arrow, and Willys was immensely pleased with the acquisition. Sales of the Willys-Knight and Stearns-Knight cars climbed to 50,000 annually, at an immense profit. The final year 1929, saw production drop from around 3,000 per year to a little over 1,000.

Willys noted that Walter Chrysler had turned the fortunes of Maxwell around, selling some 80,000 of them in 1925. Chrysler also sold 32,000 cars with the Chrysler brand on them, although a lot of them closely resembled the Chalmers body style. Chrysler had used the Detroit Chalmers plant to set up the production line for his Chrysler cars, lacking Elizabeth. The high compression six cylinder, along with the four-wheel hydraulic brakes, put Chrysler cars in a class by themselves. Top speed was about 75 miles an hour, which was within 5 miles an hour of the Packard that was significantly higher priced.

A year before, Walter Chrysler had borrowed $5 million from Chase Securities to finance his car, placing his personal assets on the line. One year later, Chrysler turned a profit of $17 million, paying Chase back, and then some.

Willys always stated that he could whip Ford if he desired. Willys had a totally new car in the planning which he believed could do just that. Introduced on May 12, 1926, simultaneously in Canada, the United States, and Australia, the Whippet was the smallest 4-cylinder car on the market. At the same time, production of the Overland marque was ended, replaced by the Whippet.

Whether by design or by oversight, the Whippet nameplate was not displayed on the first models. They had Overland hub caps and Overland radiator tags. Although advertising never mentioned Overland directly, some brochures did state that it was an Overland-Whippet. The next Whippet model, for 1926, removed any doubt that it was a Whippet, exhibiting the name in all the right places.

The Overland 93 model, which had a six-cylinder engine, quickly got changed into a Whippet 93, making it a new 1927 model, even though it was still an Overland. The four-cylinder Whippet, however, continued to make the bulk of sales.

Whippet, when introduced, had a technically refined engine with pump forced cooling, full pressurized lubrication, and four-wheel hydraulic brakes. The cars were said to be based upon European designs, which were light, sturdy, fast, dependable, economical to operate, and inexpensive to buy. They ranged in price from a fairly well-equipped lead model at $525, to the most expensive salon at $850. People mobbed the showrooms. It was estimated that on introduction day, over 14 million people visited Overland showrooms in the United States. It was neat, very well made, and stylish. Sales took off.

The 1927 4-cylinder Whippet had about 35 horsepower, and 90 ft lbs of torque. In the light, smaller body of the Whippet the mighty little engine made the Whippet feel and handle like it was lively and quick. This was a significant engine, even if Willys and the world did not recognize it as yet. It would be the basis for the “GO-DEVIL” engine that powered thousands of Jeeps. The Whippet itself may have well been the major reason why Edsel Ford kept mentioning to Henry, his father, that Ford needed to update their cars. Whippet production easily jumped to 100,000. By 1929, Willys-Overland production had hit 320,000 cars. His profit was $187 million.

Abruptly, John North Willys resigned as President. He sold all his common stock for $25 million. He did retain his title as chairman of the board. He got out before October 29, which was the day that the NY stock market began its fast track to its crash, leading the way into a world wide depression. The Stearns-Knight ended production, and was liquidated in lieu of complete bankruptcy.

In 1930, John North Willys was appointed Ambassador to Poland. He took the post immediately and continued until 1932. The same year, 1930, a new eight cylinder was brought out, with remarkably bad timing; and the Whippet name was replaced by Willys.

Around June, 1932, Willys introduced a restyled line of 1933 Willys and Willys-Knight cars. Sales were a disaster, with 571 Willys-Knight Great Six, 6,775 Willys Six and 1,022 Willys Eight models built in a six-month period. Production came to an end in October, 1932, and the plants sat idle. The Canadian operation was shut down completely and all assets sold off. Willys would not have a Canadian presence again until 1937.

The Great Depression of the 1930s saw numerous carmakers go out of business and the Willys enterprises went into bankruptcy reorganization in 1933.

Willys-Overland had lost some $35 million between 1929 and 1932. A new four-cylinder Willys 77 was announced for 1933, along with a six-cylinder that was never produced, but in 1933, Willys-Overland went into receivership. Willys quickly returned to try to save the company. Without any preamble or mention of marital problems, Willys divorced his wife of many years in 1934, and quickly remarried in 1935. He became the President again of Willys-Overland also in 1935. However, while at his home in the Bronx, New York, John North Willys suffered a fatal stroke on August 26, 1935 after recovering completely from a previous heart attack that he had in May. He was interred in the Kensico Cemetery in Valhalla, NY.

In 1936, the bankruptcy recovery plan had been accepted. The Willys Real Estate Realization Corp. was formed and all real estate owned by Willys-Overland was transfered to it. A new company, Willys-Overland Motors, Inc. took over auto manufacturing, renting its offices and plants from WRERC which, due to the shrinkage of the company (from 315,000 cars in 1928 to 29,918 in 1933) did not need the whole complex. WRERC itself was able to rent out office and plant facilties not used by Willys-Overland, which emerged as Willys-Overland Motors, Incorporated. It remained profitable, just not as profitable as it had been. A sort of consortium of management types ran the company, and were cautious about making any changes.

The company continued on, going through the World War II years with the awarding of the open bid contract to build the GP (Jeep) for the military. After resuming production for the public in 1946, Willys-Overland Motors chose to stick with its unique trucks for the civilian markets until 1951. Its cars, made from 1951 to 1955, had little success, and the company refocused on its durable trucks.

In 1953, Kaiser Corporation bought out Willys-Overland Motors, and renamed it Willys Motors Company. In 1963 the company re-organized, becoming Kaiser-Jeep Corporation, and the Willys name disappeared into history (though Overland was used as a premium Jeep model, and a concept Jeep Willys was created).

In 1970, Kaiser Industries decided to leave the automobile business, selling Kaiser-Jeep to American Motors Corporation, which had been created from the merger of Hudson and Nash. Not ten years later, after being hit by fuel crises and lack of acceptance of its new designs, AMC sold a major portion to Renault, of France, in 1979. Chrysler Corporation acquired all of AMC in 1989 from Renault, which had been unable to find acceptance for its own new designs. In 1998, though flush with success, Chrysler was acquired by Daimler-Benz of Germany, becoming the Daimler Chrysler Company, AG. It was then acquired by Cerberus Capital Management in 2007 and, following bankruptcy, was divided between an employee retirement fund, Fiat, and the U.S. and Canadian governments.

From 1953, every ten years or so, Willys-Overland had been reorganized or purchased.

Someone as vibrant and honest as John North Willys surely would not be pleased at the turn of events.

Most of this article was written by Bill Watson and found at allpar.com/corporate/bios,willys.html (John North Willys (of Overland) biography. Some was from Wikipedia.

Charles Yale Knight

1868-1940

In 1901 Charles Yale Knight bought an air-cooled, single-cylinder three-wheeler whose noisy valves annoyed him. He believed that he could design a better engine and began experimenting with a sleeve valve engine in August 1903, inventing his double sleeve principle in 1904. Backed by Chicago entrepreneur L.B. Kilbourne, Knight and Kilbourne was formed as a company around 1905, operating from 19 Huron St, Chicago. A number of engines were constructed, followed by the “Silent Knight” touring car, which was shown at the 1906 Chicago Auto Show.

Knight’s design had two cast-iron sleeves per cylinder, one sliding inside the other with the piston inside the inner sleeve. The sleeves were operated by small connected rods actuated by an eccentric shaft. They had ports cut out at their upper ends. The design was remarkably quiet, and the sleeve valves needed little attention. It was, however, more expensive to manufacture due to the precision grinding required on the sleeves’ surfaces. It also used more oil at high speeds and was harder to start in cold weather. There was also a Royalty fee to be paid to Knight and Kilbourne for manufacturers wishing to build the Knight engine under license.

The sleeve valve engine was revolutionary in the following ways: less noise than a poppet valve engine – hence the term “Silent Knight” which Knight and Kilbourne sold their vehicle under; more efficient than a poppet valve engine due to large valve openings and hemispherical cylinder head design which is difficult to achieve with poppet valves; more durable than a poppet valve engine as there were no valve springs to weaken over time, nor valves to decarbonize and re-seat. In fact, the Knight engine showed an increase in compression and power over time as any carbon build-up actually tended to increase the close fit around the double sleeves.

Although he was initially unable to sell his Knight Engine in the United States, a long sojourn in England, involving extensive further development and refinement by Daimler, supervised by their consultant Dr Frederick Lanchester,[10] eventually secured Daimler and several luxury car firms as customers willing to pay his expensive premiums. He first patented the design in England in 1908. Knight and Kilbourne manufactured enough cars in the 1905 – 1908 period to interest other manufacturers, particularly those of the high quality and expensive category: Daimler, Minerva, Mercedes, Panhard et Levessor.

The patent for the US was granted in 1910. As part of the licensing agreement, “Knight” was to be included in the car’s name. F.B. Stearns was the first American manufacturer to adopt the Knight engine in 1911. It was not until 1913 that Charles Knight met with J.N. Willys during a trip to England. After hearing about the Knight engine on the boat, Willys rented a Daimler Knight, complete with chauffeur, covered 4,500 miles during his 15-day vacation and was ecstatic over the engine. On his return to America, he bought the Edwards Motor Co of New York, which in turn gave him the license to build his own Knight engined cars.

It was the Willys Knight cars that made the Knight engine famous because J.N. Willys was not only an amazing salesman but put so much effort into reducing the manufacturing costs. Willys Overland was the most successful sleeve valve manufacturer, producing almost half a million between 1914 and 1933, from a small farm single cylinder 3 H.P. lighting plant to a 65 bhp V-8.

This wasn’t to be the largest, nor the most complex of the Knight Sleeve Valve engines. The French manufacturer Avions Voisin also built many large Knight Sleeve valve engined vehicles, including a V-12 and a straight 12-cylinder configuration. Along with an 8-liter special that completed the worlds 24-hour race in 1927 with an average speed of just over 113 mph.

Six-cylinder Daimler sleeve valve engines were used in the first British tanks in WW1, up to and including the Mark IV. As a result of the tendency of the engines to smoke and hence give away the tank positions, Harry Ricardo was brought in, and devised a new engine which replaced the sleeve valve starting with the Mark V tank.

Among the companies using Knight’s technology were Avions Voisin, Daimler (1909–1930s) including their V12 Double Six, Panhard (1911–39), Mercedes (1909–24), Willys (as the Willys-Knight, plus the associated Falcon Knight), Stearns, Mors, Peugeot, and Belgium’s Minerva company that was forced to stop their sleeve-valve line of engines as a result of the limitations imposed on them by the winners of WWII, some thirty companies in all. Itala also experimented with rotary and sleeve valves in their ‘Avalve’ cars.

The Great Depression of 1929 put an end to most of the U.S. autos using the sleeve valve engine due to the high cost.

Taken from: en.wikipedia.org/wik/sleeve_valve